Advionics is specialized in aluminum milling. We are equipped with modern CNC-milling machinery. We have a fully installed milling centre with an automated warehouse which provides 24/7 parts production of aluminum milling. The complementary smaller CNC milling stations guarantee flexibility to meet the customer’s demands for the production of mechanical parts. Our machinery is equipped to mill multiple materials with focus on aluminum alloys.

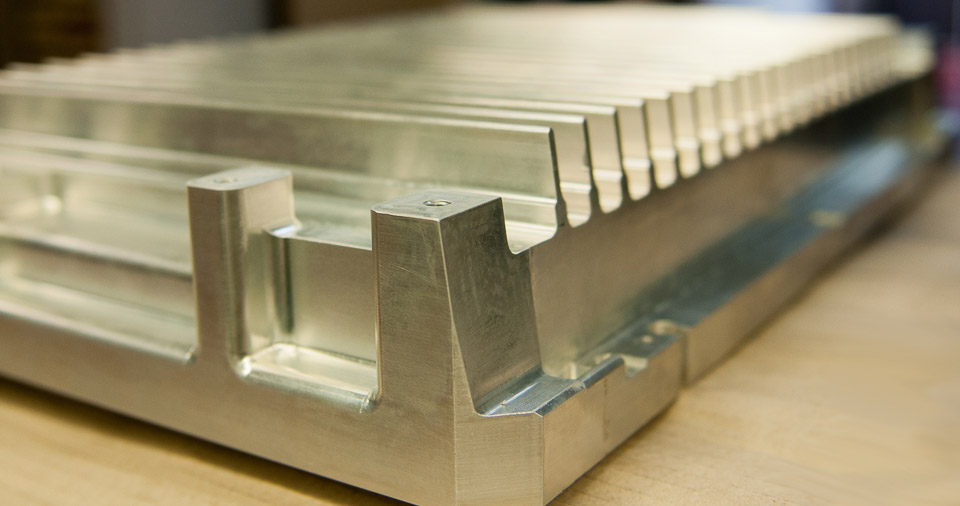

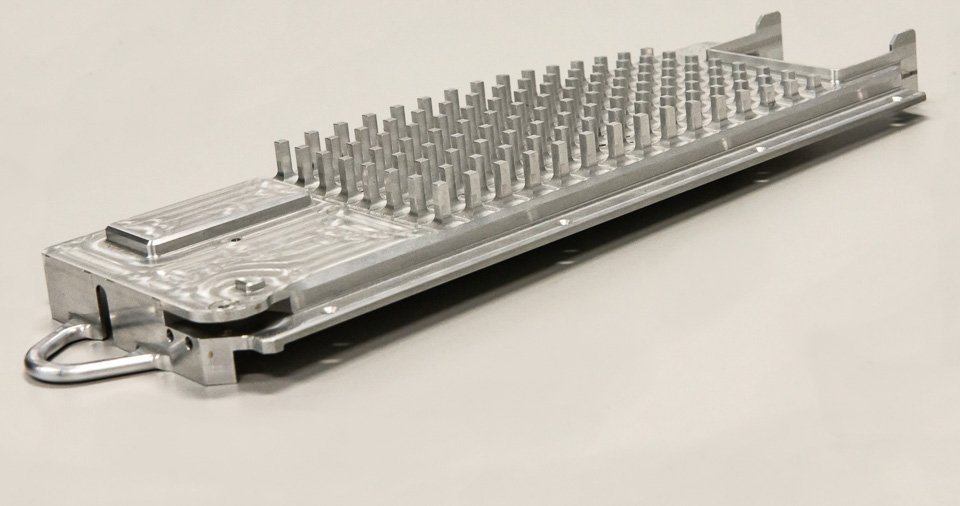

Our competence in mechanical parts production consists of the complexity of structures to be milled. High depth to radius ratio (>10) or small wall thickness (<1mm) means no challenge to us. Mechanical parts are produced by several 4-axis horizontally milling machines and additional turning lathe. In order to prove accuracy, all parts are measured by means of 3D coordinate measuring device.

However, we don’t stop at aluminum milling, deburring is at least as important for (airborne) electromechanical parts as milling itself.

As a standard, all our mechanical parts get a vibratory finish. The vibrating interaction of water, compound, media and our mechanical parts produces the required surface finish and deburring. It is followed by a visual inspection and manually deburring where necessary.

For some very complex or larger products, aluminum milling is not an option and aluminum casting is required. However casting hasn’t the precision of aluminum milling . We have a substantial experience to mill your casted product to the precision you want.

To give your milled parts the best protection possible, we can provide them with a protective chemical coating, to prevent corrosion.

Your milled parts also can be finished with protective paintwork. We offer wet paint spraying and can accomplish all of your demands.

We perform also the assembly of different mechanical parts. There are no restrictions concerning the kind of connection: welded, glued, screwed with or without screw thread coils, press fitted, etc.