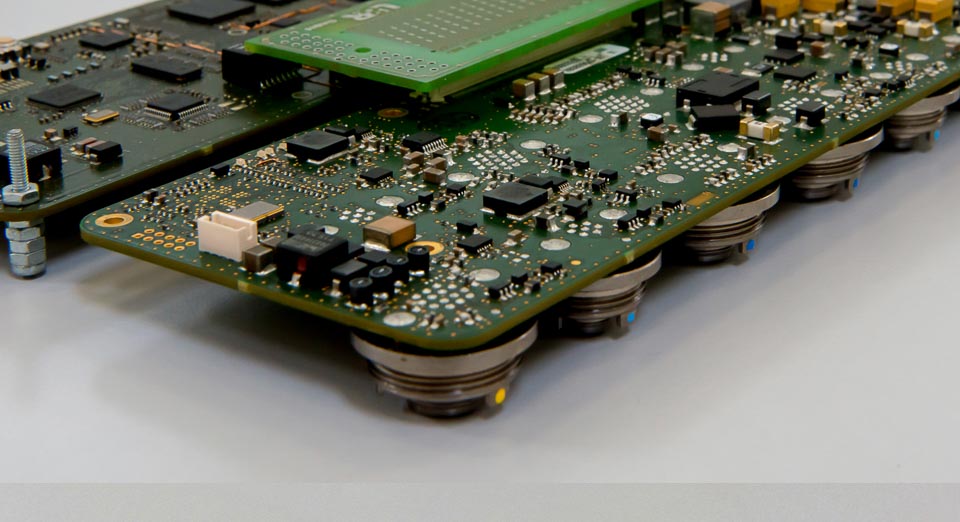

For over 50 years we have been fulfilling the requirements of high reliability sectors of industry, such as defense, aerospace, space and avionics. We are familiar with supply of PCB assemblies which meet the very highest quality and reliability standards. Through the years there has been regularly invested in our production equipment and lay-out, resulting in a state of the art machinery for your circuit board assembly.

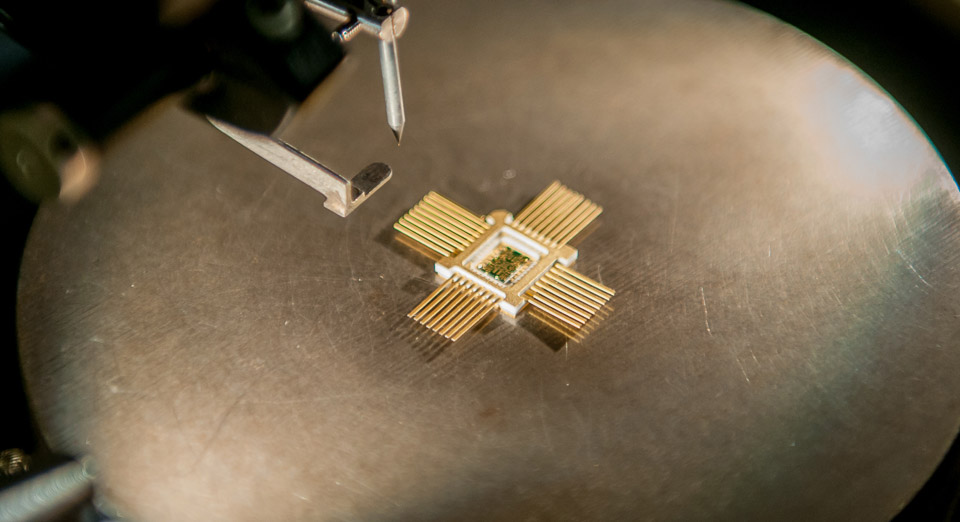

Our in-house procurement department has established close partnerships with multiple PCB fabricate houses so that we can propose the right match for your needs (urgency, design complexity, volume and cost). We have full capability to assemble all types of SMD components, such as 01005 chips, µBGA, POP, placement, leadless devices and odd-form components.

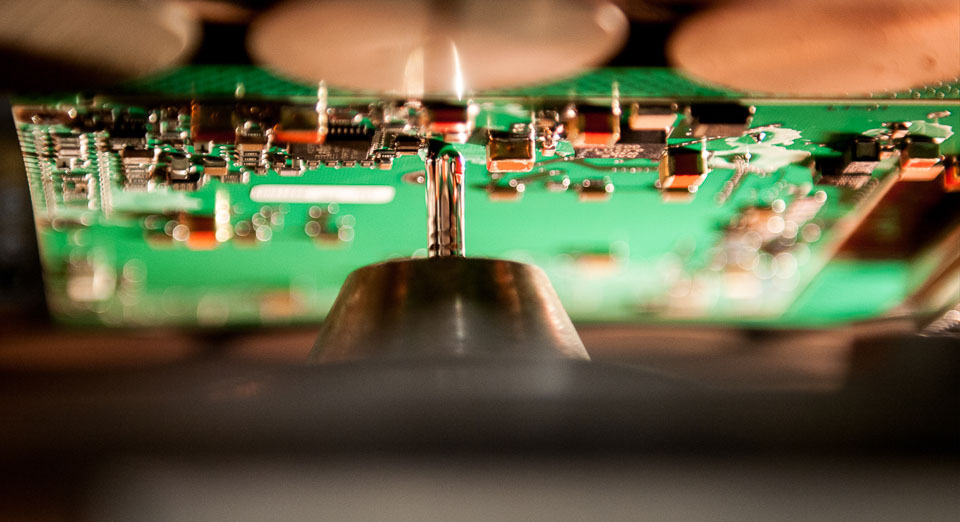

Conventional leaded components are prepared in-house and are selectively soldered or – if possible – through intrusive soldering. For over 20 years we have been soldering complete boards onto silver or gold plated cooling plates and housings for high frequency applications using our vacuum equipped vapor phase soldering machine. Soldering inspection according to IPC-A610 / J-STD-001 is completed through AOI, high resolution X-ray and microscope by a very experienced staff.

Conformal coating (UV or non-UV) of the circuit board assembly is accomplished by means of a Nordson Asymtec and PVA coater. If desired, the boards can be cleaned ultrasonically or conventionally. Since most of our customers did not shift to lead-free, all our processes are equipped for both lead-free and lead-based production. The production is driven by our Production Support Software that enables paperless manufacturing on each workstation. Full traceability can be offered.

For the production of your circuit board assembly we have a fully equipped Class 10.000 Clean Room.